We all know mercury is a silvery metal in liquid form. Probably most of us first saw it in childhood at the mirror like shining bulb end of thermometer when doctor pushed the thermometer in to our mouth .

In ancient days mercury was thought to have medicinal properties which will prolong life !! 🙂 Qín Shǐ Huáng Dì, Emperor of China, died due to drinking a mercury and powdered jade mixture formulated by Qin alchemists thinking he will attain immortality. The Emperor’s tomb contained flowing mercury models of rivers in china. Ancient Egyptians and Greeks used mercury in cosmetics and other ointments.

Mercury is highly corrosive to aluminium and is classified as Corrosive Substances (Class 8) in model regulations. Recent study of corrosive effect of Mercury on Aluminium states that heavy and sudden corrosion will take place leading to pitting and cracking which increases by presence of humidity. On mild steel the corrosion rate is.25mm/year.

Mercury is traditionally sold in flasks measuring about 2.5 litres (34.5 kg or 76 lb.). This weight is equal to one Spanish quintals; Spain was one of the biggest producers of mercury. Mercury is having high density of 13.54562 g/cm3

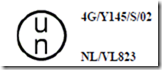

For sea transport IMDG Code list mercury under UN 2809 MERCURY Class 8 with special instruction prohibiting transport by hovercraft and other ships constructed of aluminium. IMDG Code allows flasks up to 3L for transporting Mercury by sea, including the empty flask the total gross mass per flask may be around 45-50 kg.

There is a new convention by United Nations named Minamata Convention for protecting human health and the environment from anthropogenic emissions and releases of mercury and mercury compounds.

If you are shipping Mercury or any article containing Mercury by Sea it is a mandatory requirement that you receive training to handle same as per IMDG Code.

For details of training click here Click here for Elearning

Related articles

- IMDG Code e-learning (shashikallada.com)

- UNEP Minamata Convention (cardinalenvironment.wordpress.com)

- Global Treaty Demands Mercury Reduction in Mining, But Not in Vaccines or Dental Fillings (govtslaves.info)

- Mercury Treaty Signed in Minamata (ictsd.org)

- There’s Mercury In Your Mascara, And The UN Is OK With That (huffingtonpost.com)

- Guyana unveils 5-year plan to reduce mercury use (kaieteurnewsonline.com)

- UN sees mercury use phase-out within 3 decades (boston.com)