In the last article, ‘Stowage and Segregation of Dangerous Goods on Container Ships’, dated 20th May, we looked at the provisions of stowage of containerized dangerous goods on container ships. Let us look at the basic stowage and segregation provisions for carriage of dangerous goods in packaged from and in solid bulk form on general cargo ships.

Flammable gases or flammable liquids having a flashpoint of less than 23°C c.c, must be stowed on deck only, unless otherwise approved by the Administration and must be stowed at least 3 m from any potential source of ignition. Here possible sources of ignition may include open fires, machinery exhausts, galley uptakes, electrical outlets and electrical equipment including those on refrigerated or heated cargo transport units unless they are of certified safe type. For interpreting what is certified type, for cargo spaces, refer to SOLAS II:2/19.3.2 and for refrigerated or heated cargo transport units refer to Recommendation published by the international Electrotechnical Commission, in particular IEC 60079.

When explosives are loaded the compartments or holds and containers must be locked to pervert unauthorized access however when in emergency access to the locked places must be able to be gained without delay. If the cargo compartment floors are not fitted with closed boarded wood the loading/unloading equipment and process must ensure no sparks can occur. If the cargo gets wet all handling operations must be stopped unless specialist advise from shipper clears same. Personnel involved in cargo operations must be briefed prior work regarding the potential risks and necessary precaution. When explosives belonging to different compatibility groups are loaded they must be stowed not less than 6 meters from each other unless mixed loading is permitted between the involved compatibility groups as per section 7.2.7 of IMDG Code.

Non containerized flammable liquids packaged in plastics jerricans, plastics drums, plastics IBCs must always be stowed on deck. There are special requirements for stowage of FISHMEAL, UNSTABILIZED (UN 1374), FISHMEAL, STABILIZED (UN 2216, class 9) and KRILL MEAL (UN3497), SEED CAKE (UN 1386), AMMONIUM NITRATE BASED FERTILIZER, UN 2071 and certain other goods.

When feeds or other edible substances intended for consumption by humans or animals, foodstuff, is loaded it will require segregation ‘separated from’ toxic, radioactive and corrosive dangerous goods and Dangerous goods in other classes which has segregation reference in column 16 (16b in 37th amendment of IMDG Code).

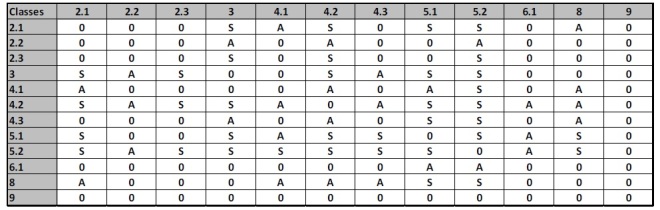

There are four segregation rules for dangerous goods loaded in conventional way on board ships.

- Away from: Effectively segregated so that the incompatible goods cannot interact dangerously in the event of an accident but may be transported in the same compartment or hold or on deck, provided a minimum horizontal separation of 3 metres, projected vertically is obtained.

- Separated from: In different compartments or holds when stowed under deck. Provided the intervening deck is resistant to fire and liquid, a vertical separation, i.e. in different compartments, may be accepted as equivalent to this segregation. For on deck stowage, this segregation means a separation by a distance of at least 6 metres horizontally.

- Separated by a complete compartment or hold from: Either a vertical or a horizontal separation. If the intervening decks are not resistant to fire and liquid, then only a longitudinal separation, i.e. by an intervening complete compartment or hold, is acceptable. For on deck stowage, this segregation means a separation by a distance of at least 12 metres horizontally. The same distance has to be applied if one package is stowed on deck, and the other one in an upper compartment.

- Separated longitudinally by an intervening complete compartment or hold from: Vertical separation alone does not meet this requirement. Between a package under deck and one on deck, a minimum distance of 24 m, including a complete compartment, must be maintained longitudinally. For on deck stowage, this segregation means a separation by a distance of at least 24 metres longitudinally.

Segregation rules between containerized dangerous goods and those loaded in conventional ways are different. Dangerous goods stowed in the conventional way must be segregated from goods transported in closed containers in accordance with segregation provisions showed above except that for “away from” is required, no segregation between the packages and the closed cargo transport units is required; and where “separated from” is required, the segregation between the packages and the closed cargo transport units may be as for “away from”.

Segregation between Bulk dangerous goods and packaged dangerous goods must be in accordance with the table shown in section 7.6.3.5.2 of IMDG Code where all 4 segregation terms have different rules from those listed above.

For full details of the requirements of stowage and segregation of dangerous goods loaded on general cargo ships refer to chapter 7.6 of IMDG Code, individual entries in chapter 3.2 and IMSBC Code as applicable.