Guidance in this article is applicable only for packaged dangerous goods. Segregation recommendation explained below for port areas may also be applied to CFS/ICD for safety reasons.

Correct classification, packaging, marking, labelling, segregation, securing cargo in container and documentation is the prerequisite to ensure safety of life at sea and prevention of pollution. Packaged dangerous goods whether containerized or non-containerized when kept in port areas waiting for loading on to vessel or to be taken out by consignee may require segregation from one another. Transport regulations contain mandatory segregation rules recognizing the danger involved and available/practical emergency response in each mode of transport. Segregation requirements varies from regulation to regulation; in multimodal transport the most stringent segregation rule of one mode is acceptable by other modes.

Class 1, Explosives, other than 1.4S, and Class 7, Radioactive Materials, should generally be handled direct loading and delivery. Port authorities must formulate special plans for keeping these classes when necessary under special safety, emergency response and security measures. Class 6.2, Infectious substances, must only be handled as direct loading or delivery, never be kept in port areas.

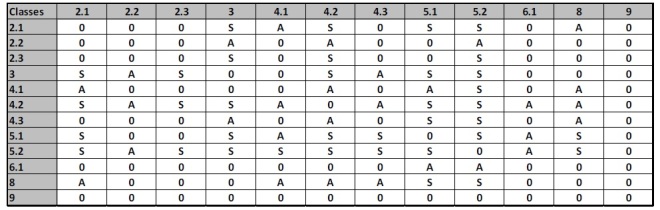

Other classes may be segregated as in below table.

Non-containerized Packages & IBCs

0 = no segregation necessary unless required by the individual schedules

A = away from – minimum 3 m separation required

S = separated from – in open areas, minimum 6 m separation required in sheds or warehouses, minimum 12 m separation required unless separated by an approved fire wall

Closed containers & portable tanks

0 = no segregation necessary

A = away from – no segregation necessary

S = separated from – in open areas, longitudinally and laterally, minimum 3 m separation required, in sheds or warehouses longitudinally and laterally, minimum 6 m separation required unless separated by an approved fire wall

Example segregation check -“away from”

- Non containerized packages class 2.2 and 3

Intersection between classes 2.2 and 3 in above table is A = away from – minimum 3 m separation required.

- Container one carrying class 2.2, container two carrying class 3

Intersection between classes 2.2 and 3 in above table is A = away from – no segregation necessary.

In the above example non containerized packages need ‘away from’ 3 meter segregation however when the packages are in different containers no segregation is needed.

Example segregation check -“separated from”

- Non containerized packages class 2.1 and 3

Intersection between classes 2.1 and 3 in above table is S = separated from

– in open areas, minimum 6 m separation required

– in sheds or warehouses, minimum 12 m separation required unless separated by an approved fire wall

- Container one carrying class 2.2, container two carrying class 3

Intersection between classes 2.1 and 3 in above table is S = separated from

– in open areas, longitudinally and laterally, minimum 3 m separation required, – – in sheds or warehouses longitudinally and laterally, minimum 6 m separation required unless separated by an approved fire wall

Example segregation check – “Subsidiary Risk”

- Non containerized packages UN 1072 OXYGEN, COMPRESSED Class 2.2 Subsidiary Risk 5.1 and UN 1001 ACETYLENE, DISSOLVED Class 2.1

Intersection between classes 2.1 and 2.2 in above table is O = no segregation necessary

Intersection between subsidiary risk of UN 1072 class 5.1 to main class of UN 1001 2.1 is S = separated from

More stringent segregation requirement is S= separated from.

– in open areas, minimum 6 m separation required

– in sheds or warehouses, minimum 12 m separation required unless separated by an approved fire wall

- Container one carrying UN 1072 OXYGEN, COMPRESSED Class 2.2 Subsidiary Risk 5.1 and container two carrying UN 1001 ACETYLENE, DISSOLVED Class 2.1

Intersection between classes 2.1 and 2.2 in above table is O = no segregation necessary

Intersection between subsidiary risk of UN 1072 class 5.1 to main class of UN 1001 2.1 is S = separated from

– in open areas, longitudinally and laterally, minimum 3 m separation required, – in sheds or warehouses longitudinally and laterally, minimum 6 m separation required unless separated by an approved fire wall

Example segregation check – “Segregation Groups”

- Non containerized packages of UN 1502 SODIUM PERCHLORATE, Class 5.1 and UN 1512 ZINC AMMONIUM NITRITE, Class 5.1

Intersection between classes 5.1 and 5.1 in above table is O= no segregation necessary unless required by the individual schedules

UN 1502’s Column 16 of IMDG Code 36-12 says “Separated from” ammonium compounds and cyanides.

UN 1512 is listed in segregation group 2 Ammonium compounds in section 3.1.4.4 hence applicable segregation is S = separated from

– in open areas, minimum 6 m separation required

– in sheds or warehouses, minimum 12 m separation required unless separated by an approved fire wall

- Container one carrying UN 1502 SODIUM PERCHLORATE, Class 5.1 and Container two UN 1512 ZINC AMMONIUM NITRITE, Class 5.1

Intersection between classes 5.1 and 5.1 in above table is O= no segregation necessary unless required by the individual schedules

UN 1502’s Column 16 of IMDG Code 36-12 says “Separated from” ammonium compounds and cyanides.

UN 1512 is listed in segregation group 2 Ammonium compounds in section 3.1.4.4 hence applicable segregation is S = separated from

– in open areas, longitudinally and laterally, minimum 3 m separation required,

– in sheds or warehouses longitudinally and laterally, minimum 6 m separation required unless separated by an approved fire wall.

—-

Ports should develop their own lay out plan for keeping and segregating dangerous goods based on quantitative risk analysis and segregation requirement. For more information refer to Revised Recommendations on the safe transport of dangerous cargoes and related activities in port areas published by IMO.

A port which stack all dangerous goods containers together is not a safe port!!!