Pressurized deodorants, insecticides, medicinal sprays, spray paint cans, cooking spray etc. are called aerosols. Norwegian engineer Erik Rotheim patented the first aerosol can way back in 1927. Over the years much modifications came however the basic principle remains same.

Transport regulations defines Aerosols or aerosol dispensers as non-refillable receptacles made of metal, glass or plastics and containing a gas compressed, liquefied or dissolved under pressure, with or without a liquid, paste or powder, and fitted with a release device allowing the contents to be ejected as solid or liquid particles in suspension in a gas, as a foam, paste or powder or in a liquid state or in a gaseous state.

More than 15 billion aerosols are made globally per annum!

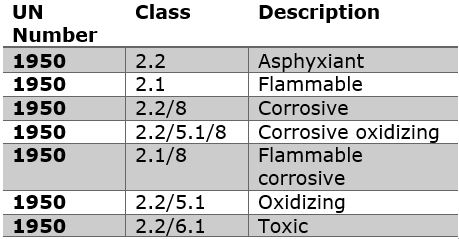

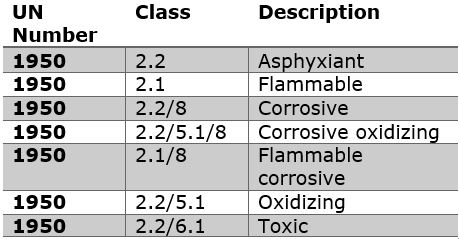

Aerosols is listed under UN Number 1950 with class/ division as “2”. Special Provision 63 explains the classification depending on the content and propellant.

Aerosols are flammable (Class 2.1) if the contents include 85% by mass or more flammable components and the chemical heat of combustion is 30 kJ/g or more.

Aerosols are asphyxiant (Class 2.2) if the contents contain 1% by mass or less flammable components and the heat of combustion is less than 20 kJ/g.

Aerosols are toxic (Class 6.1) or corrosive (Class8) if the contents are toxic or corrosive. However the contents of 6.1 & 8 packing group I are prohibited. Similarly, toxic gases (Class 2.3) is prohibited to be used as propellant. Flammable aerosols classification for spray aerosols and foam aerosols are different. Section 31 of United Nations Manual of Test and Criteria lays out same. Every aerosol dispenser shall be provided with protection against inadvertent discharge.

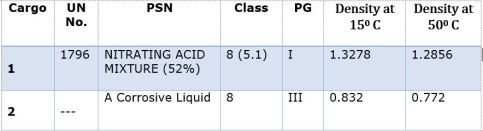

The possible classification of aerosols is as below

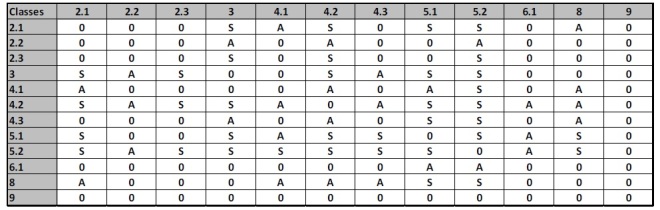

Aerosols can be either max 1 litre capacity or above 1 litre, the change in the capacity triggers changes in stowage and segregation rules on board ships. As long as the capacity of aerosol is maximum 1 litre, irrespective of the class and subsidiary risk, for segregation purpose it is considered as class 9. If the capacity of aerosol is above 1 litre the segregation is as per the class and subsidiary risks assigned.

IMDG Code stowage and segregation for aerosols are “Protected from sources of heat. For AEROSOLS with a maximum capacity of 1 l, Category A. Segregation as for class 9 but “Separated from” class 1 except division 1.4. For AEROSOLS with a capacity above 1 l. Category B. Segregation as for the appropriate sub-division of class 2.

It is the responsibility of shipper to indicate the capacity of aerosol in dangerous goods declaration if same is above 1 litre.

There are special provisions for transporting waste aerosols by sea and it is permitted only on short international voyages, transportation of waste aerosols on long international voyages can only be undertaken if specially approved by competent authority.

Aerosols with a capacity not exceeding 50 mℓ containing only non-toxic constituents are not subject to the provisions of IMDG Code.

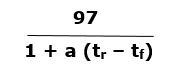

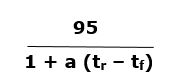

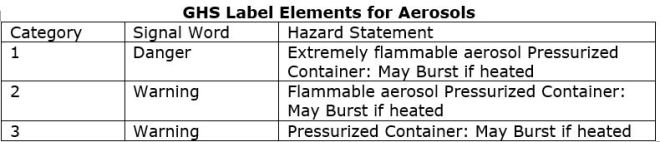

Under Globally Harmonized System of Classification and Labelling (GHS) aerosols are classified into three categories.

Refer to chapter 2.3 of GHS 5th revised edition for full details.

For sea transport refer to special provisions assigned to UN Number 1950 and section 6.2.4 of IMDG Code for testing.

Have you ever read the usage guidance and warnings printed on the deodorant can?

Deodorants can be deadly, it has caused fire, explosion, death due to improper usage. Cars have gone up in flame due to deodorant left in it. Inhaling solvents in the deodorant may cause cardiac abnormality.

Whether you transport aerosols or not, following below precautionary statements while using/storing your body sprays, insecticides sprays and other aerosols can prevent you from injury or fire.

- Keep away from heat, hot surfaces, sparks, open flames and other ignition sources. No smoking.

- Do not spray on an open flame or other ignition source

- Do not pierce or burn, even after use

- Protect from sunlight

- Do not expose to temperatures exceeding 50 °C/ 122 °F.

- Keep out of reach of children

For more information on aerosols visit European Aerosol Federation http://www.aerosol.org/ Asian Aerosol Federation – covering Australia, China, India, Japan, New Zealand & Thailand- http://aerosol-asia.org/